- 您现在的位置:买卖IC网 > Sheet目录19083 > DCE.91.132.BVM (LEMO)TOOL POSITNER FOR DPC.91.701.V

?

?

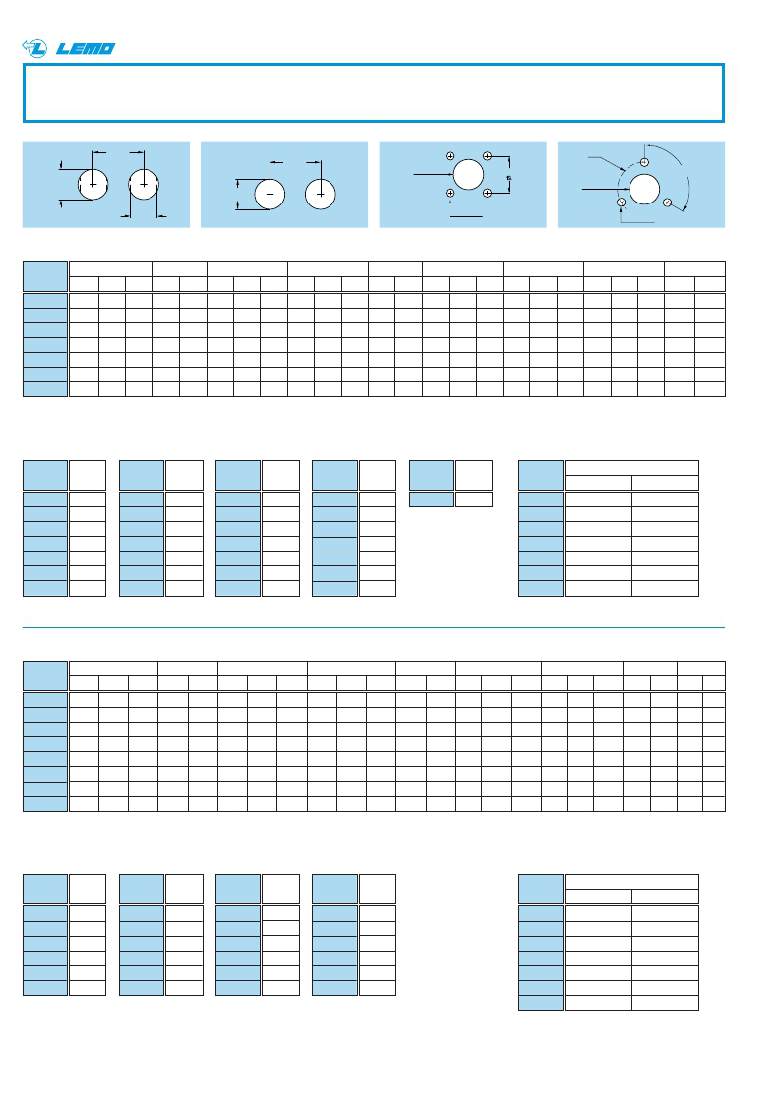

Panel cut-outs

B + 0.1

B + 0.1

P1-P3-P4-P9

L mini

P2-P5-P10-P11

L mini

P6-P7

0

P8

?C

0

120 ° x 3

B + 0.1

? A + 0.1

? A + 0.1

B series

0

0

0

Series

?A

P1

B

L

P2

?A L

?A

P3

B

L

?A

P4

B

L

P5

? A 2)

L

?A

P6

B

H

?A

P8

B

C

?A

P9

B

L

P10

?A L

00

7.1

6.4

12.5 7.1 11.5 –

– – – – – – – – –

–

– –

–

7.1

–

12

–

–

0B

1B

2B

3B

4B

5B

9.1

12.1

15.1

18.2

25.2

35.2 1)

8.3

10.6

13.6

16.6

23.6

33.6

14.5 9.1 13.5 14.1 12.6 20.1 10.1 9.1 15.0 8.30 10.5 – –

18.5 – – 16.1 14.6 22.0 14.1 12.6 21.0 11.17 14.0 – –

22.5 – – 19.2 17.1 28.0 16.1 15.1 23.0 13.95 18.0 – –

27.0 – – – – – 20.2 18.6 29.5 – – – –

36.0 – – – – – 25.2 23.6 36.1 – – – –

44.0 – – – – – 35.2 33.6 47.1 – – 3.3 35.2

–

–

–

–

–

34

– –

– –

– –

– –

– –

2.8 35.2

–

–

–

–

–

47

9.1

12.1

15.1

18.2

25.2

35.2

8.3

10.6

13.6

16.6

23.6

33.6

15

19

23

27

36

47

–

11.1

–

–

–

–

–

17

–

–

–

–

1) for using the tapered washer a round hole ? 36 mm apply. 2) tolerance: + 0.02

Note:

0

Cut-out types

Mounting nut torque

Model

Type

Model

Type

Model

Type

Model

Type

Model

Type

Series

Torque (Nm)

Metal shell Plastic shell 4)

ECG

EEG

EGG

EFG

EHG

EJG

EKG

P1

P1

P1

P2

P1

P5

P1

ENG

ENY

ESG

EXG

EYG

FAG

FWG

P1

P1

P1/P2

P2/P10

P1/P10

P1

P9

HCG

HEG

HGG

HHG

HMG

HNG

PEG

P3

P9

P9

P9

P9

P9

P1

PFG

PKG

R qq

S qq

XBG

XPF

XRB

P1

P1

P4

P4/P9 3)

P2

P2

P2

YHG

P9

00

0B

1B

2B

3B

4B

5B

1.0

2.5

4.5

6.0

9.0

12.0

17.0

0.4

0.4

0.7

0.8

1.0

5.0

–

Note: 3) in series 1B use P9.

S series

Note: 4) these values apply when metal shell are mounted with insulating washer.

Series

?A

P1

B

L

P2

?A L

?A

P3

B

L

?A

P4

B

L

P5

? A 2)

L

?A

P6

B

H

?A

P7

B

H

P10

?A L

P11

?A L

00

0S

7.1

9.1

6.4

8.3

12.5

14.5

7.1

9.1

11.5

13.5

–

12.1

–

10.6

–

20.0

–

10.1

–

9.1

–

15

– – – – –

– – – – –

– – –

– – –

–

–

– – –

– 9.1 16

1S

12.1

10.6

18.5

12.1

19.0

14.1

12.6

21.0

12.1

10.6

18

11.92 15.5 3.3 12.1 12.7

2.7 11.1 12.4 11.1

17 12.1 19

2S

3S

4S

5S

6S

15.1

18.2

25.2

35.2 1)

48.3

13.6

16.6

23.6

33.6

45.6

22.5

27.0

36.0

44.0

58.0

15.1

18.2

25.2

35.2

48.3

21.5

27.0

34.0

44.0

58.0

16.1

20.2

25.2

35.2

48.3

14.6

18.6

23.6

33.6

45.6

22.0

30.0

36.0

47.0

60.0

16.1

20.2

25.2

35.2

48.3

15.1

18.6

23.6

33.6

45.6

23

29

36

47

60

– – 3.3 15.1 15.5

– – 3.3 18.2 18.0

– – – – –

– – 4.4 35.2 36.8

– – – – –

– – –

– – –

– – –

– – –

– – –

–

–

–

–

–

– – –

– – –

– – –

– – –

– – –

using the tapered washer a round hole ? 36 mm apply. 2) tolerance: + 0.02

1) for

Note:

0

Cut-out types

Mounting nut torque

Model

Type

Model

Type

Model

Type

Model

Type

Series

Torque (Nm)

Metal shell Plastic shell 6)

EBC

EBD

EBS

ECP

EEP

EHP

P6

P6

P7

P1

P1

P2/P1

ERA

ERC

ERD

ERN

ERS

EXP

P1

P1

P1

P1

P2

P2/P10

EWB

FAA

HCP

HGP

HGW

PSA

P3

P1/P2 3)

P3 4)

P3

P11

P1

PSP

PSS

RAD

SWH

P1

P1

P1/P2 5)

P4

1 N = 0.102 kg

0S

1S

2S

3S

4S

5S

2.5

4.5

6.0

9.0

12.0

17.0

0.4

0.7

0.8

1.0

5.0

–

Note:

3)

in series 6S use P2.

4)

use only ? A in 1S series.

6S

22.0

–

152

5)

in series 4S and 5S use P2.

Note: 6) these values apply when metal shell are mounted with insulating washer.

www.lemo.com

发布紧急采购,3分钟左右您将得到回复。

相关PDF资料

FXO-HC335R-14.31818

OSCILLATOR 14.31818 MHZ 3.3V SMD

OV4ZBBBB

LED OPTIMAL IV STAR BLUE

8W-26.000MBA-T

OSC 26.000 MHZ 3.3V SMT

P51-50-S-F-P-5V-000-000

SENSOR 50PSIS 1/4 NPT 5V

P51-15-S-F-P-5V-000-000

SENSOR 15PSIS 1/4 NPT 5V

P51-750-S-E-P-5V-000-000

SENSOR 750PSIS 3/8 UNF 5V

P51-500-S-E-P-5V-000-000

SENSOR 500PSIS 3/8 UNF 5V

DCE.91.131.BVC

TOOL POSITNER FOR DPC.91.701.V

相关代理商/技术参数

DCE.91.132.CVC

功能描述:折皱器 PSTNR F. CRMP CONTCT

RoHS:否 制造商:Hirose Connector 类型: 描述/功能:Cable and Shield Crimper

DCE.91.132.CVM

功能描述:折皱器 PSTNR F. CRMP CONTCT

RoHS:否 制造商:Hirose Connector 类型: 描述/功能:Cable and Shield Crimper

DCE.91.133.BVC

功能描述:折皱器 POSITNER F CRIMP CTS

RoHS:否 制造商:Hirose Connector 类型: 描述/功能:Cable and Shield Crimper

DCE.91.133.BVCM

制造商:LEMO connectors 功能描述:

DCE.91.133.BVCW

功能描述:折皱器 B-SERIES M/F POSITNR SMPTE 3K 1.3mm CRMP

RoHS:否 制造商:Hirose Connector 类型: 描述/功能:Cable and Shield Crimper

DCE.91.133.BVCY

制造商:LEMO 功能描述:TOOL POSITIONER FOR CRIMP PIN 制造商:LEMO connectors 功能描述:TOOLING - DCE.91.133.BVCY

DCE.91.133.BVM

功能描述:折皱器 PSTNR F. CRMP CONTCT

RoHS:否 制造商:Hirose Connector 类型: 描述/功能:Cable and Shield Crimper

DCE.91.134.BVC

功能描述:折皱器 PSTNR F. CRMP CONTCT

RoHS:否 制造商:Hirose Connector 类型: 描述/功能:Cable and Shield Crimper